Eccentric Fine Boring Tools

- Used for finish boring application from diameter 5mm up to 25mm (any intermediary size on demand).

- Available with adjustment options of ±0.1mm (LC 10 microns) & ±0.3mm (LC 30 microns).

- User friendly & quick adjustment ensures minimum loss time.

- Guaranteed repeatability by using recommended torque for locking.

- Most economic solution for finish boring with precise adjustment in microns.

- Tailor made tools with similar concept also available for the application of Back Boring and OD Turning

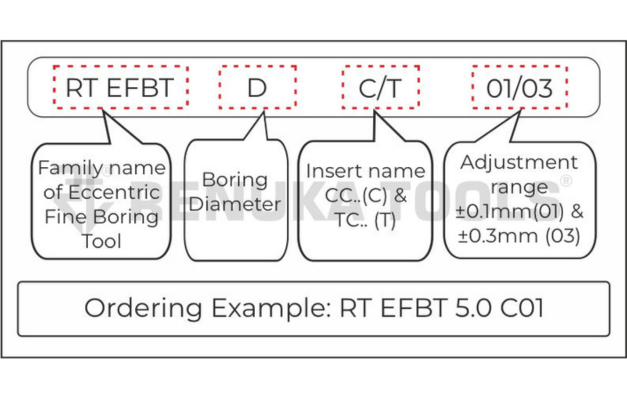

Nomenclature Code Key for Ordering Eccentric Fine Boring Tool

- For TC.. Inserts Range ±0.1mm

- For TC.. Inserts Range ±0.3mm

- For CC.. Inserts Range ±0.1mm

- For CC.. Inserts Range ±0.3mm

- Back Boring & Facing Tool

- OD Turning Tool

- Operating Instructions

- Precautionary Measures

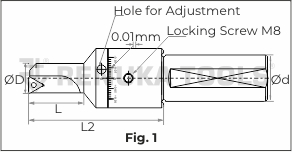

Eccentric Fine Boring Tool For TC.. Inserts Range ±0.1mm

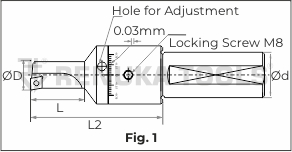

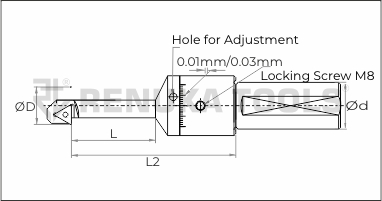

Specifications Table : With Adjustment Option ±0.1mm (LC-10 Microns).

| Fig No. | Sr. No. | Item Code | Insert | D | L | L2 |

|---|---|---|---|---|---|---|

|

Fig 1 |

1 |

RT EFBT 8.0 - 8.9 T01 |

TC..06T1 |

8.0 - 8.9 |

24 |

67 |

|

2 |

RT EFBT 9.0 - 9.9 T01 |

TC..06T1 |

9.0 - 9.9 |

27 |

70 |

|

|

3 |

RT EFBT 10 - 10.9 T01 |

TC..06T1 |

10 - 10.9 |

30 |

73 |

|

|

4 |

RT EFBT 11 - 11.9 T01 |

TC..06T1 |

11 - 11.9 |

33 |

76 |

|

|

5 |

RT EFBT 12 - 12.9 T01 |

TC..06T1 |

12 - 12.9 |

36 |

79 |

|

|

6 |

RT EFBT 13 - 13.9 T01 |

TC..06T1 |

13 - 13.9 |

39 |

82 |

|

|

7 |

RT EFBT 14 - 14.9 T01 |

TC..06T1 |

14 - 14.9 |

42 |

85 |

|

|

8 |

RT EFBT 15 - 15.9 T01 |

TC..0902 |

15 - 15.9 |

45 |

88 |

|

|

9 |

RT EFBT 16 - 16.9 T01 |

TC..0902 |

16 - 16.9 |

48 |

91 |

|

|

10 |

RT EFBT 17 - 17.9 T01 |

TC..0902 |

17 - 17.9 |

51 |

94 |

|

|

11 |

RT EFBT 18 - 18.9 T01 |

TC..0902 |

18 - 18.9 |

54 |

97 |

|

|

12 |

RT EFBT 19 - 19.9 T01 |

TC..0902 |

19 - 19.9 |

57 |

100 |

|

|

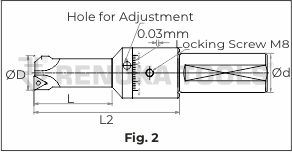

Fig 2 |

13 |

RT EFBT 20 - 20.9 T01 |

TC..0902 |

20 - 20.9 |

60 |

103 |

|

14 |

RT EFBT 21 - 21.9 T01 |

TC..0902 |

21 - 21.9 |

63 |

106 |

|

|

15 |

RT EFBT 22 - 22.9 T01 |

TC..0902 |

22 - 22.9 |

66 |

109 |

|

|

16 |

RT EFBT 23 - 23.9 T01 |

TC..0902 |

23 - 23.9 |

69 |

112 |

|

|

17 |

RT EFBT 24 - 25.0 T01 |

TC..0902 |

24 - 25.0 |

70 |

113 |

Notes

- Least count for ±0.1mm adjustable EFBT is 10 microns, for ±0.3mm adjustable EFBT is 30 microns.

- Shank Diameter "Ød" for all of the above tools is 25mm, Collar Diameter is 32mm & Shank Length is 56mm.

- Locking Screw provided is M8 with recommended torque of 8N.m. for consistent results. Allen key also provided.

- Above table gives the entire range of diameters, exact diameter to be mentioned in requirement eg. 15.7mm.

- Further options available till diameter 30mm on demand, will be tailor made with a lead time of 2-3 weeks.

- Maximum recommended material removal is 0.5mm diametrically.

- Lead time of 1-2 weeks for all options.

- Tailor made tools with similar concept also available for the application of back boring & OD boring.

- Inserts are not included with the tools.

- Please refer the table below these notes for the spare details.

- Diameter range 'D' calculated considering 0.4mm insert nose radius.

Spare Details

| Sr. No. | Insert | Insert Screw | Torx |

|---|---|---|---|

|

1 |

TC.. 06T1 |

M2.0 |

T-6 |

|

2 |

TC.. 0902 |

M2.2 |

T-6 |

|

3 |

TC.. 1102 |

M2.5 |

T-7 |

Eccentric Fine Boring Tool For TC.. Inserts Range ±0.3mm

Specifications Table : With Adjustment Option ±0.3mm (LC-30 Microns).

| Fig No. | Sr. No. | Item Code | Insert | D | L | L2 |

|---|---|---|---|---|---|---|

|

Fig 1 |

1 |

RT EFBT 8.0 - 8.9 T03 |

TC..06T1 |

8.0 - 8.9 |

24 |

67 |

|

2 |

RT EFBT 9.0 - 9.9 TC03 |

TC..06T1 |

9.0 - 9.9 |

27 |

70 |

|

|

3 |

RT EFBT 10 - 10.9 TC03 |

TC..06T1 |

10 - 10.9 |

30 |

73 |

|

|

4 |

RT EFBT 11 - 11.9 TC03 |

TC..06T1 |

11 - 11.9 |

33 |

76 |

|

|

5 |

RT EFBT 12 - 12.9 TC03 |

TC..06T1 |

12 - 12.9 |

36 |

79 |

|

|

6 |

RT EFBT 13 - 13.9 TC03 |

TC..06T1 |

13 - 13.9 |

39 |

82 |

|

|

7 |

RT EFBT 14 - 14.9 TC03 |

TC..06T1 |

14 - 14.9 |

42 |

85 |

|

|

8 |

RT EFBT 15 - 15.9 TC03 |

TC..0902 |

15 - 15.9 |

45 |

88 |

|

|

9 |

RT EFBT 16 - 16.9 TC03 |

TC..0902 |

16 - 16.9 |

48 |

91 |

|

|

10 |

RT EFBT 17 - 17.9 TC03 |

TC..0902 |

17 - 17.9 |

51 |

94 |

|

|

11 |

RT EFBT 18 - 18.9 TC03 |

TC..0902 |

18 - 18.9 |

54 |

97 |

|

|

12 |

RT EFBT 19 - 19.9 TC03 |

TC..0902 |

19 - 19.9 |

57 |

100 |

|

|

Fig 2 |

13 |

RT EFBT 20 - 20.9 TC03 |

TC..0902 |

20 - 20.9 |

60 |

103 |

|

14 |

RT EFBT 21 - 21.9 TC03 |

TC..0902 |

21 - 21.9 |

63 |

106 |

|

|

15 |

RT EFBT 22 - 22.9 TC03 |

TC..0902 |

22 - 22.9 |

66 |

109 |

|

|

16 |

RT EFBT 23 - 23.9 TC03 |

TC..0902 |

23 - 23.9 |

69 |

112 |

|

|

17 |

RT EFBT 24 - 25.0 TC03 |

TC..0902 |

24 - 25.0 |

70 |

113 |

Notes

- Least count for ±0.1mm adjustable EFBT is 10 microns, for ±0.3mm adjustable EFBT is 30 microns.

- Shank Diameter "Ød" for all of the above tools is 25mm, Collar Diameter is 32mm & Shank Length is 56mm.

- Locking Screw provided is M8 with recommended torque of 8N.m. for consistent results. Allen key also provided.

- Above table gives the entire range of diameters, exact diameter to be mentioned in requirement eg. 15.7mm.

- Further options available till diameter 30mm on demand, will be tailor made with a lead time of 2-3 weeks.

- Maximum recommended material removal is 0.5mm diametrically.

- Lead time of 1-2 weeks for all options.

- Tailor made tools with similar concept also available for the application of back boring & OD boring.

- Inserts are not included with the tools.

- Please refer the table below these notes for the spare details.

- Diameter range 'D' calculated considering 0.4mm insert nose radius.

Spare Details

| Sr. No. | Insert | Insert Screw | Torx |

|---|---|---|---|

|

1 |

TC.. 06T1 |

M2.0 |

T-6 |

|

2 |

TC.. 0902 |

M2.2 |

T-6 |

|

3 |

TC.. 1102 |

M2.5 |

T-7 |

Eccentric Fine Boring Tool For CC.. Inserts Range ±0.1mm

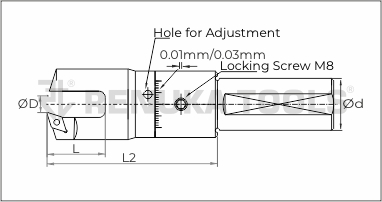

Specifications Table :With Adjustment Option ±0.1mm (LC-10 Microns).

| Fig No. | Sr. No. | Item Code | Insert | D | L | L2 |

|---|---|---|---|---|---|---|

|

Fig 1 |

1 |

RT EFBT 5.0 - 5.9 C01 |

CC..0301 |

5.0 - 5.9 |

15 |

58 |

|

2 |

RT EFBT 6.0 - 6.9 C01 |

CC..0401 |

6.0 -6.9 |

18 |

61 |

|

|

3 |

RT EFBT 7.0 - 7.9 C01 |

CC..0401 |

7.0 - 7.9 |

21 |

64 |

|

|

4 |

RT EFBT 8.0 - 8.9 C01 |

CC..0401 |

8.0 - 8.9 |

24 |

67 |

|

|

5 |

RT EFBT 9.0 - 9.9 C01 |

CC..0602 |

9.0 - 9.9 |

27 |

70 |

|

|

6 |

RT EFBT 10 - 10.9 C01 |

CC..0602 |

10 - 10.9 |

30 |

73 |

|

|

7 |

RT EFBT 11 - 11.9 C01 |

CC..0602 |

11 - 11.9 |

33 |

76 |

|

|

8 |

RT EFBT 12 - 12.9 C01 |

CC..0602 |

12 - 12.9 |

36 |

79 |

|

|

9 |

RT EFBT 13 - 13.9 C01 |

CC..0602 |

13 - 13.9 |

39 |

82 |

|

|

10 |

RT EFBT 14 - 14.9 C01 |

CC..0602 |

14 - 14.9 |

42 |

85 |

|

|

11 |

RT EFBT 15 - 15.9 C01 |

CC..0602 |

15 - 15.9 |

45 |

88 |

|

|

12 |

RT EFBT 16 - 16.9 C01 |

CC..0602 |

16 - 16.9 |

48 |

91 |

|

|

13 |

RT EFBT 17 - 17.9 C01 |

CC..0602 |

17 - 17.9 |

51 |

94 |

|

|

14 |

RT EFBT 18 - 18.9 C01 |

CC..0602 |

18 - 18.9 |

54 |

97 |

|

|

15 |

RT EFBT 19 - 19.9 C01 |

CC..0602 |

19 - 19.9 |

57 |

100 |

|

|

Fig 2 |

16 |

RT EFBT 20 - 20.9 C01 |

CC..0602 |

20 - 20.9 |

60 |

103 |

|

17 |

RT EFBT 21 - 21.9 C01 |

CC..0602 |

21 - 21.9 |

63 |

106 |

|

|

18 |

RT EFBT 22 - 22.9 C01 |

CC..0602 |

22 - 22.9 |

66 |

109 |

|

|

19 |

RT EFBT 23 - 23.9 C01 |

CC..0602 |

23 - 23.9 |

69 |

112 |

|

|

20 |

RT EFBT 24 - 25.0 C01 |

CC..0602 |

24 - 25.0 |

70 |

113 |

Notes

- Least count for ±0.1mm adjustable EFBT is 10 microns, for ±0.3mm adjustable EFBT is 30 microns.

- Shank Diameter "Ød" for all of the above tools is 25mm, Collar Diameter is 32mm & Shank Length is 56mm.

- Locking Screw provided is M8 with recommended torque of 8N.m. for consistent results. Allen key also provided.

- Above table gives the entire range of diameters, exact diameter to be mentioned in requirement eg. 15.7mm.

- Further options available till diameter 30mm on demand, will be tailor made with a lead time of 2-3 weeks.

- Maximum recommended material removal is 0.5mm diametrically.

- Lead time of 1-2 weeks for all options.

- Tailor made tools with similar concept also available for the application of back boring & OD boring.

- Inserts are not included with the tools.

- Please refer the table below these notes for the spare details.

- Diameter range 'D' calculated considering 0.4mm insert nose radius ( and 0.2mm for insert CC.. 0301 ).

Spare Details

| Sr. No. | Insert | Insert Screw | Torx |

|---|---|---|---|

|

1 |

CC.. 0301 |

M2.0 |

T-6 |

|

2 |

CC.. 0401 |

M2.2 |

T-6 |

|

3 |

CC.. 0602 |

M2.5 |

T-7 |

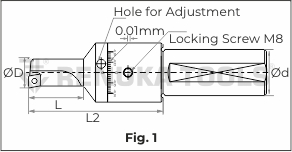

Eccentric Fine Boring Tool For CC.. Inserts Range ±0.3mm

Specifications Table : With Adjustment Option ±0.3mm (LC-30 Microns).

| Fig No. | Sr. No. | Item Code | Insert | D | L | L2 |

|---|---|---|---|---|---|---|

|

Fig 1 |

1 |

RT EFBT 5.0 - 5.9 C03 |

CC..0301 |

5.0 - 5.9 |

15 |

58 |

|

2 |

RT EFBT 6.0 - 6.9 C03 |

CC..0401 |

6.0 -6.9 |

18 |

61 |

|

|

3 |

RT EFBT 7.0 - 7.9 C03 |

CC..0401 |

7.0 - 7.9 |

21 |

64 |

|

|

4 |

RT EFBT 8.0 - 8.9 C03 |

CC..0401 |

8.0 - 8.9 |

24 |

67 |

|

|

5 |

RT EFBT 9.0 - 9.9 C03 |

CC..0602 |

9.0 - 9.9 |

27 |

70 |

|

|

6 |

RT EFBT 10 - 10.9 C03 |

CC..0602 |

10 - 10.9 |

30 |

73 |

|

|

7 |

RT EFBT 11 - 11.9 C03 |

CC..0602 |

11 - 11.9 |

33 |

76 |

|

|

8 |

RT EFBT 12 - 12.9 C03 |

CC..0602 |

12 - 12.9 |

36 |

79 |

|

|

9 |

RT EFBT 13 - 13.9 C03 |

CC..0602 |

13 - 13.9 |

39 |

82 |

|

|

10 |

RT EFBT 14 - 14.9 C03 |

CC..0602 |

14 - 14.9 |

42 |

85 |

|

|

11 |

RT EFBT 15 - 15.9 C03 |

CC..0602 |

15 - 15.9 |

45 |

88 |

|

|

12 |

RT EFBT 16 - 16.9 C03 |

CC..0602 |

16 - 16.9 |

48 |

91 |

|

|

13 |

RT EFBT 17 - 17.9 C03 |

CC..0602 |

17 - 17.9 |

51 |

94 |

|

|

14 |

RT EFBT 18 - 18.9 C03 |

CC..0602 |

18 - 18.9 |

54 |

97 |

|

|

15 |

RT EFBT 19 - 19.9 C03 |

CC..0602 |

19 - 19.9 |

57 |

100 |

|

|

Fig 2 |

16 |

RT EFBT 20 - 20.9 C03 |

CC..0602 |

20 - 20.9 |

60 |

103 |

|

17 |

RT EFBT 21 - 21.9 C03 |

CC..0602 |

21 - 21.9 |

63 |

106 |

|

|

18 |

RT EFBT 22 - 22.9 C03 |

CC..0602 |

22 - 22.9 |

66 |

109 |

|

|

19 |

RT EFBT 23 - 23.9 C03 |

CC..0602 |

23 - 23.9 |

69 |

112 |

|

|

20 |

RT EFBT 24 - 25.0 C03 |

CC..0602 |

24 - 25.0 |

70 |

113 |

Notes

- Least count for ±0.1mm adjustable EFBT is 10 microns, for ±0.3mm adjustable EFBT is 30 microns.

- Shank Diameter "Ød" for all of the above tools is 25mm, Collar Diameter is 32mm & Shank Length is 56mm.

- Locking Screw provided is M8 with recommended torque of 8N.m. for consistent results. Allen key also provided.

- Above table gives the entire range of diameters, exact diameter to be mentioned in requirement eg. 15.7mm.

- Further options available till diameter 30mm on demand, will be tailor made with a lead time of 2-3 weeks.

- Maximum recommended material removal is 0.5mm diametrically.

- Lead time of 1-2 weeks for all options.

- Tailor made tools with similar concept also available for the application of back boring & OD boring.

- Inserts are not included with the tools.

- Please refer the table below these notes for the spare details.

- Diameter range 'D' calculated considering 0.4mm insert nose radius.

Spare Details

| Sr. No. | Insert | Insert Screw | Torx |

|---|---|---|---|

|

1 |

CC.. 0301 |

M2.0 |

T-6 |

|

2 |

CC.. 0401 |

M2.2 |

T-6 |

|

3 |

CC.. 0602 |

M2.5 |

T-7 |

Back Boring & Facing Tool

Notes

- Minimum Diameter ØD = Ø10.0mm

- Maximum Diameter ØD = Ø25.0mm

- Maximum L/D Ratio = 2.5

- Maximum Length L = 50mm

- Shank Diameter Ød = 25mm

- All tools with eccentric concept for the application of back boring will be tailor made as per requirements.

- Shank Diameter "Ød" for all the eccentric tools is 25mm, Collar Diameter is 32mm & Shank Length is 56mm.

- Lead time of 2-3 weeks.

OD Turning Tool

Notes

- Minimum Diameter ØD = Ø8.0mm

- Maximum Diameter ØD = Ø22.0mm

- Maximum L/D Ratio = 2.5

- Maximum Length L = 50mm

- Shank Diameter Ød = 25mm

- All tools with eccentric concept for the application of OD turning will be tailor made as per requirements.

- Shank Diameter "Ød" for all the eccentric tools is 25mm, Collar Diameter is 32mm & Shank Length is 56mm.

- Lead time of 2-3 weeks.

Operating Instructions

- The tool is initially set on zero mark on the scale. (pic 1)

- After clamping the tool in the hydro grip or side-lock adaptor or ER collet chuck adaptor, measure the exact diameter on the pre-setter or by using a precise dial indicator

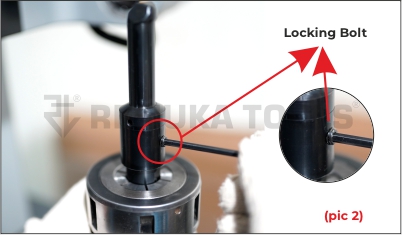

- In case you wish to adjust the diameter, loosen the Locking Screw of M8 with the provided Allen key of 4mm. (pic 2)

- Use the same allen key to adjust the diameter by using the scale mentioned on the body of the tool. (pic 3)

- The smallest division is the least count of the tool, adjust accordingly and then recheck if the required size is achived. (pic 1)

- If the required diameter is achieved, tighten the locking screw with a torque wrench using a torque of 8 Nm (Recommended) for precise repeatability and to ensure sufficient torque for locking (pic 2)

- The tool is now ready to use.

Precautionary Measures

- Due to constraints in the assembly tolerances, it is recommended that tools, if damaged, are to be returned to Renuka Tools for assessment/repair in a controlled environment. Commercials for repair can only be determined after detailed assessment of the damaged tool.

- Please change the locking screws and insert screws ahead in time to avoid accidents.

- Kindly change the mounting screws and insert screws ahead in time to avoid accidents.

- In case of any observed decrease in accuracy over the time of usage, kindly request Renuka Tools for servicing the tool.